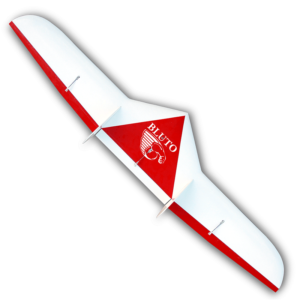

HP60

$199.00

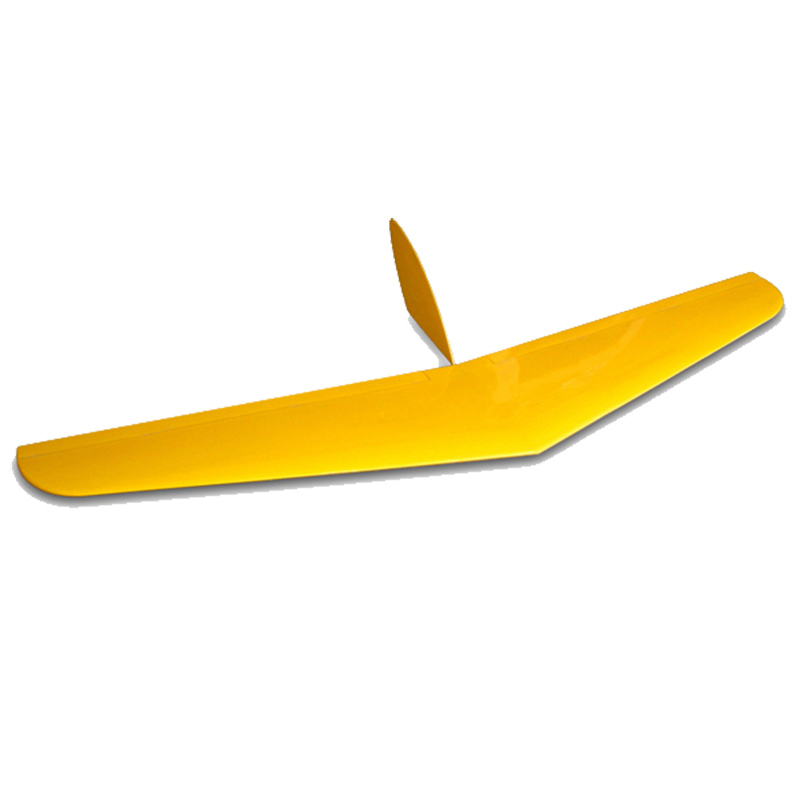

Slope Soaring Glider Kit

Span: 60″

Wing Area: 525 Sq.In.

Typical Flying Weight: 40-42 Ounces (Unballasted)

Control Channels: Two (2)

Transmitter: Digital proportional

Receiver: Mini

Servos: Micro

Battery: Small

Out of stock

Flight:

- Incredible stability & energy retention

- Phenomenal speed range

- Beautiful turns... slammed or carved

- Effortless inverted flight

- Highly responsive

- Great light lift performance

- Will "speck out" in thermals

- Very durable

Kit Includes:

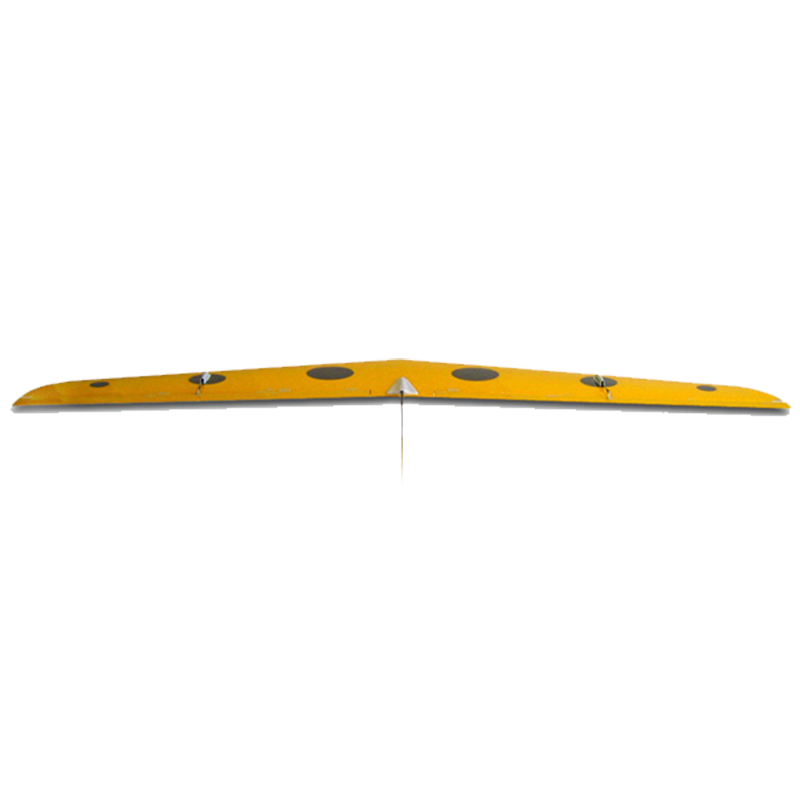

- High-load carbon fiber wing spar system

- 1.9lb Precision-cut & sanded EPP foam wing cores

- Quality balsa elevon material (weight-matched)

- Basswood drag spars

- Basswood drag spar joiner

- All control horns and linkages

- Comprehensive DVD manual with detailed graphics

You Need:

- Typical EPP construction tools and materials (knives, glues, tape, etc.)

- Heat shrink covering

- A 4 channel Digital Computer Transmitter: with Delta mixing, End-point Adjustments and Dual Rates

- A Mini Receiver : Max dimension 45 x 32 x 12 mm (1-3/4" x 1-1/4" x 1/2")

- Two (2) Micro Servos / similar to Hitec HS85MG or KST DS145MG

- One Small Battery Pack: 700 mah capacity Min.